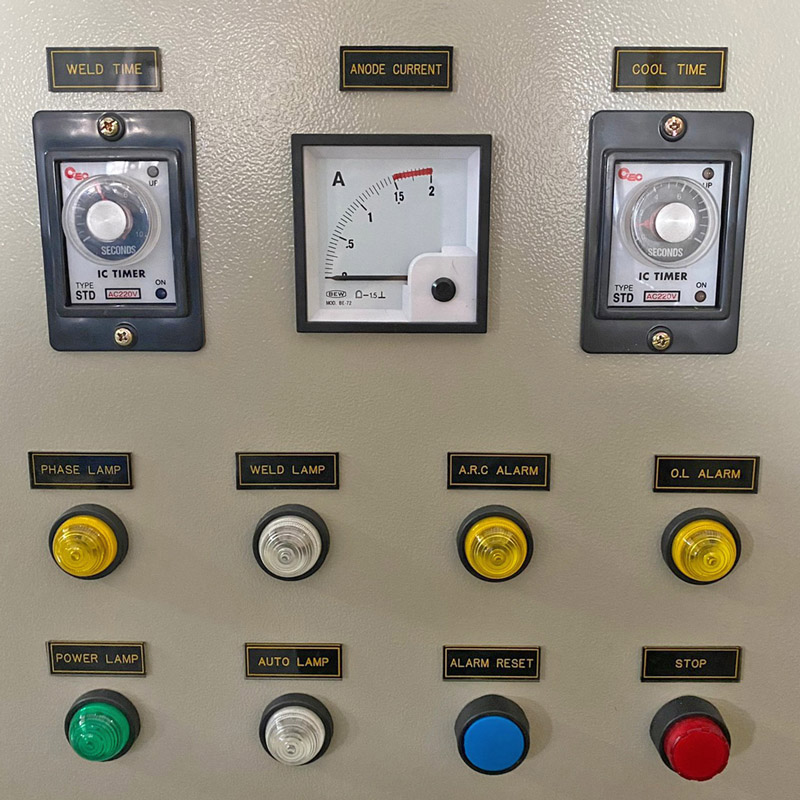

The speed of Auto Rotary table type can be controlled depends on customers' need, with several speed selections to match different demands. Furthermore, customers can not only change various molds in stations but also can adjust station numbers if needed. There are multiple stations on the rotary table in turn to increase production efficiency. It is equipped with a programmable logic control (PLC) to facilitate the manufacturing process. Through PLC, the step of welding, time duration, automatic operation, semi-automatic operation and manual operation are adjustable. The Rotary Table Type is suitable for customers who need mass production. It has high accuracy that can eliminate potential errors. The Rotary Table Type can be used to weld synthetic leather products containing PVC more than 30%, and other PU, Nylon, EVA, PEVA, PET, PETG, APET, some resins products. of ABS, etc. Among them, they need to preheat Nylon and PET before high frequency welding process.

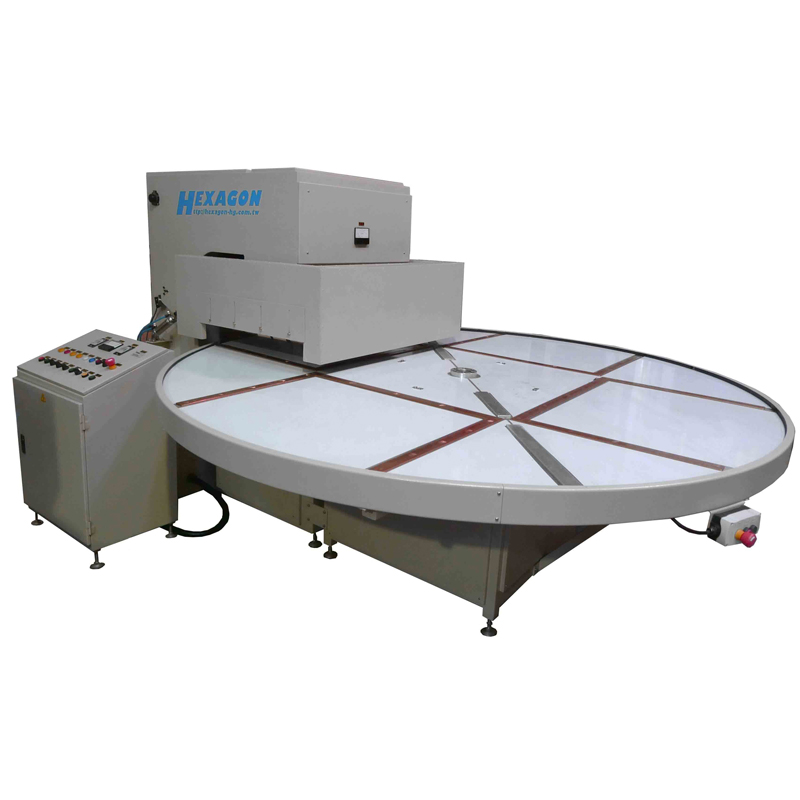

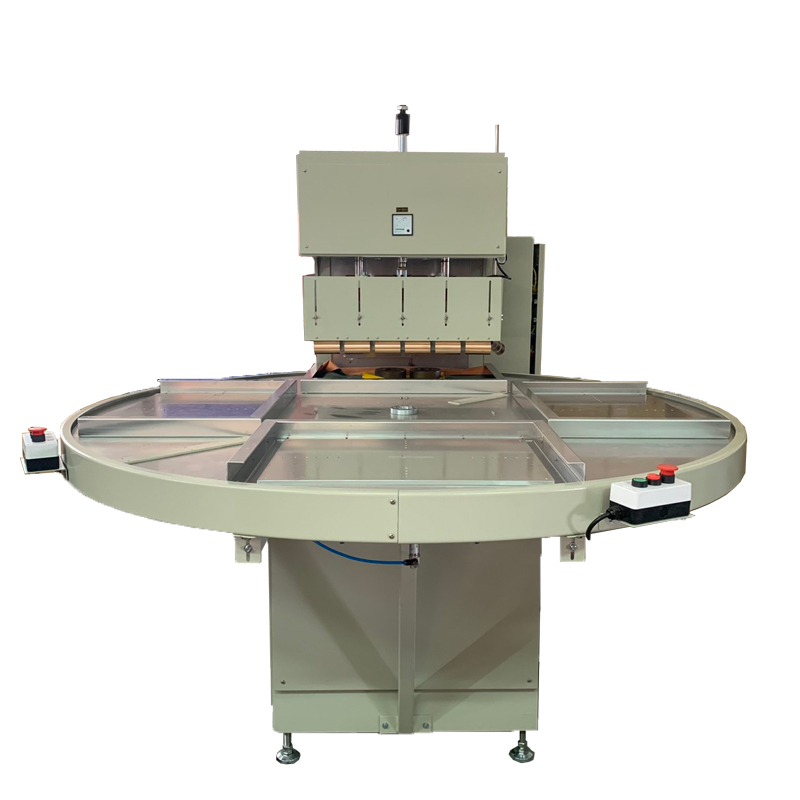

High Frequency Welding Machine – Rotary Table type

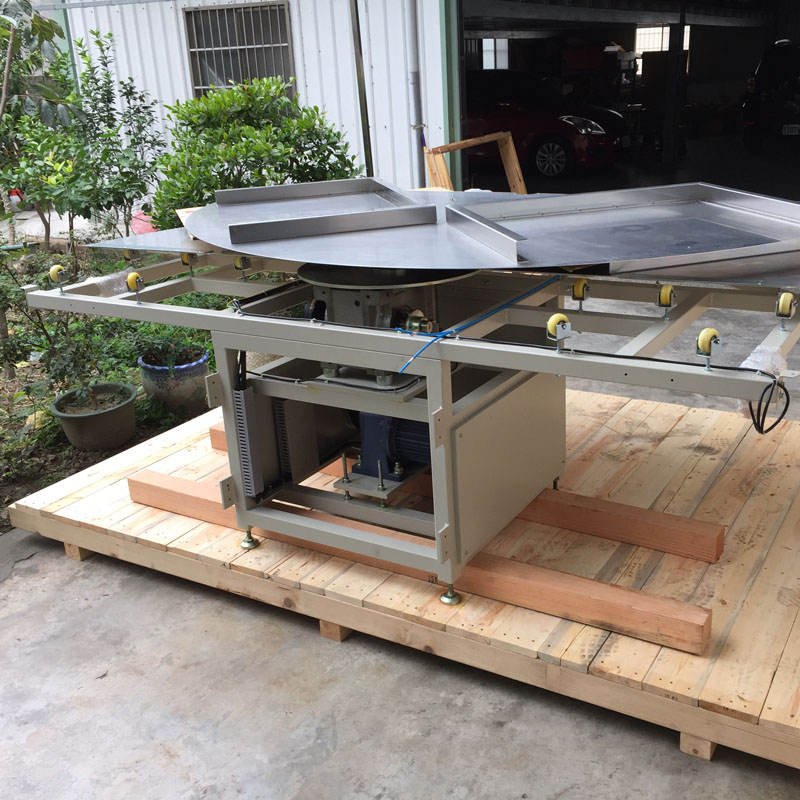

The auto rotary table high frequency PVC/PEVA welding machine is design for making complicated product. The table is positioned by an index unit resulting in accurate position. Table speed is adjustable to suit different kinds of products. Robot modules such as board feeder, plastic feeder, etc... It can easily be fitted to the system. Ideal for manufacturing binders, video boxes, cassette boxes, blister packing, etc.